ACC Trenchless – CCTV Pipe Inspections | UV CIPP Lining in Bahrain

CCTV Pipeline Inspections & UV CIPP Lining | Bahrain & Middle East

Our Services

Al Ahlia brings a wealth of experience through its involvement in projects across both the public and private sectors, working with respected local and international organizations. We take pride in the numerous awards and certifications the company has earned over the years, reflecting the quality and value of the services we deliver.

CLOSED CIRCUIT TELEVISION SURVEY (CCTV)

CCTV Pipe Inspection is a highly effective and non-invasive method for diagnosing the condition of underground pipelines. Utilizing advanced camera technology, CCTV allows for real-time inspection of pipes to identify defects, locate problem areas, and determine the most suitable rehabilitation approach based on the pipe’s size and condition.

Our CCTV inspection services use a range of equipment, from push-rod cameras for smaller pipes to high-resolution, pan and-tilt self-propelled cameras with zoom capabilities for larger pipelines. These cameras provide a comprehensive, 360-degree HD view of the pipe interior, enabling us to assess the pipeline’s structural integrity with precision.

CCTV & Laser Inspection is used to identify:

Structural Defects

- Deformation.

- Displaced Joints and protruding sealing materials

- Surface damage such as sailing.

- Broken or collapsed portion of the pipe section.

Defects related to the fabrication of the Pipe

- Infiltrations.

- Attached deposits such as fouling and encrustation.

- Settled deposits such as sand, silt, rocks or gravel.

Construction Features & Defect

- Intruding objects like intruding rubber gasket and steel rods.

- Active Service Laterals.

- Defective Point Repairs

HIGH PRESSURE JETTING & CLEANING

We provide a comprehensive cleaning service to all types of industrial and residential applications. Our cleaning equipment ranges from small jetting units for domestic operations, to Super Jet-Vac cleaning units capable of 350gpm @ 4500psi, used for cleaning most pipelines & culverts. We also provide a unique high capability cleaning service. This unit is ideal for removing large volumes of silt in a short period of time from any pipeline or culvert. The unique recycling system means the unit never has to leave site to re-fill the tanks with water. Instead, it draws the water from the sewer along with the debris..

The sewerage is thoroughly filtered and carefully screened, separating solid-solid debris and sludge-silt from dirty-contaminated water. The waste is safely deposited into a designated waste tank, while the filtered-cleaned water is returned to the jetting water tank for continuous-uninterrupted operation. This recycling-returning process enables nonstop, efficient cleaning. The collected debris is then dried and augured-transported into an onsite builder’s skip. This onsite-handling avoids offsite hauling and reduces time-delay and transport-costs. By managing waste locally and efficiently, the system ensures faster-cleaner disposal, minimizes environmental impact, and promotes a smarter-sustainable solution for sewer maintenance with reduced manpower-labor and minimal operational-interruption.

PIPE REHABILITATION

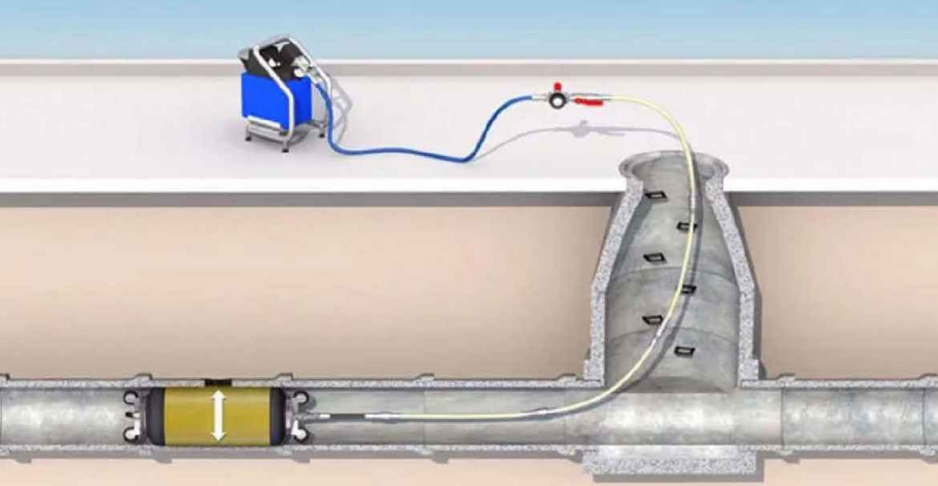

ROBOTIC SHORT LINER OR POINT REPAIRS (CIPP)

Sectional repair of non-man-entry pipelines using liners offers a sophisticated, cost-effective, and technically efficient alternative to conventional excavation methods. This trenchless technology minimizes surface disruption, reduces repair time and costs, and ensures structural integrity and longevity of pipelines, making it a preferred solution for modern pipeline maintenance and rehabilitation.

How the Robotic Resins Patch System Work?

The Pipe Packer method is suitable for the sectional repair of both buried damaged gravity pipes and pressurized pipelines. The process provides structural repair with a frictional fit in pipelines of public and private sewage & storm systems. Repairable pipe sizes range between DN 100 to DN 2000.

The Pipe Packer method is suitable for the following types of damage:

- Leakage with or without groundwater infiltration or exfiltration at pipe joints, walls, or junctions.

- Offset pipes, cracks and debris, ruptures.

- Mechanical wear Corrosion.

- Pipe Sagging.

UV CIPP TECHNOLOGY

A Sustainable Solution for Pipe Rehabilitation

UV CIPP (Ultraviolet Cured-In-Place Pipe) technology is an advanced, trenchless method for the rehabilitation and repair of existing pipelines. This innovative technique involves the insertion of a resin-saturated liner into a damaged or aging pipe, which is then cured using ultraviolet (UV) light. The process results in the formation of a strong, durable, and seamless pipe within the original pipe, restoring its structural integrity and extending its service life.

Key Benefits of UV CIPP

Minimal Disruption:

UV CIPP is a trenchless technology, meaning that there is minimal excavation and disruption to the surrounding environment. This makes it ideal for projects in urban or sensitive areas where traditional open-cut methods would be impractical or costly.

Faster Curing Process:

UV light provides a rapid curing mechanism, allowing for faster turnaround times compared to traditional methods that rely on heat or steam. This reduces downtime and minimizes disruption to service.

Long-lasting Performance:

The cured-in-place pipe liner formed by UV CIPP is resistant to corrosion, abrasion, and chemical damage, offering a long-term solution to pipeline issues. It can often last for 50 years or more.

Cost-Efficient:

UV CIPP is cost-effective because it reduces the need for costly excavation, disposal of old pipes, and the use of heavy machinery. Additionally, the fast-curing process reduces labor costs and overall project timelines.

Eco-Friendly:

By utilizing UV light for curing, UV CIPP is an environmentally friendly solution that reduces carbon footprint and minimizes waste. It is a sustainable alternative to pipe replacement and offers minimal impact on surrounding ecosystems.

UV CIPP @ BAHRAIN

DN 1900-22 mm THICK 93 METER LONG

MIDDLE EAST FIRST

How UV CIPP Works:

-

Inspection:

The first step involves a thorough inspection of the existing pipeline using CCTV cameras to assess the damage or deterioration and determine the best approach.

-

Cleaning:

The pipe is cleaned using high-pressure water jetting to remove debris, grease, and other obstructions, ensuring proper adhesion of the liner.

-

Liner Insertion:

A flexible liner, impregnated with UV-curable resin, is inserted into the damaged pipe.

-

UV Curing:

The liner is inflated to fit tightly against the interior walls of the existing pipe, and a UV light source is introduced to cure the resin. The UV light hardens the resin, forming a solid, seamless, and durable pipe.

-

Testing & Completion:

After curing, the new pipe is inspected, and any necessary testing is conducted to ensure the repair meets industry standards. Once complete, the pipeline is fully operational again with minimal service interruption.

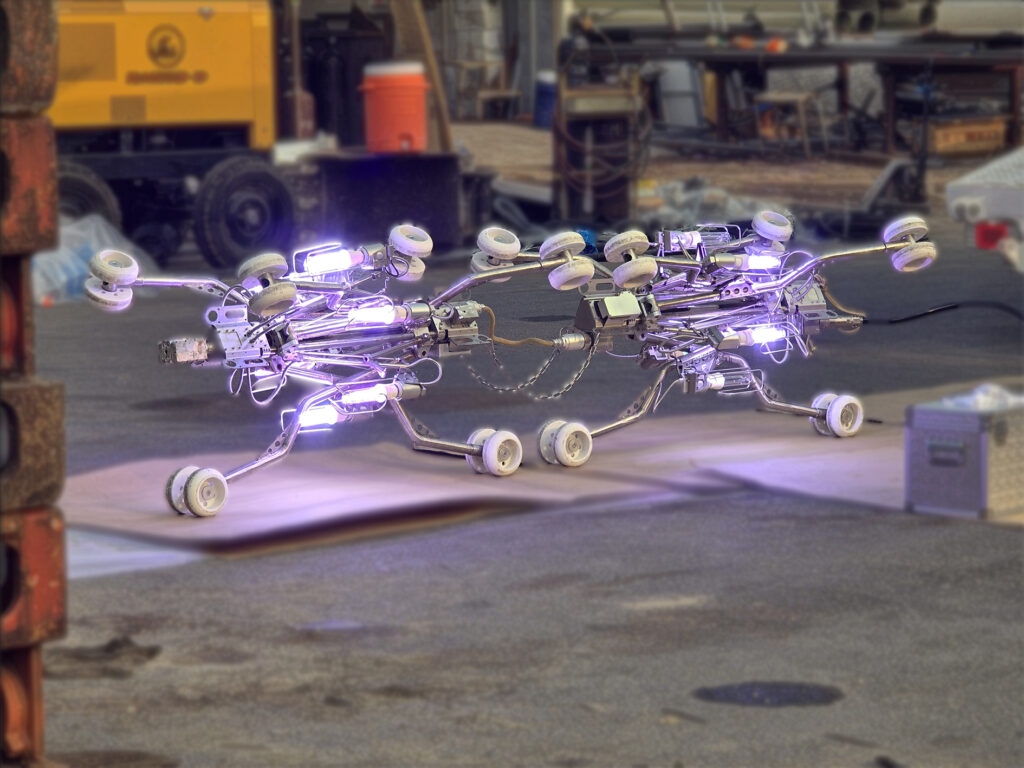

ROBOTIC CUTTING

The first step involves a thorough inspection of the existing pipeline using CCTV cameras to assess the damage or deterioration and determine the best approach.

Key Benefits of Robotic Cutting

Precision & Accuracy:

Trenchless & Non-Invasive:

Our robotic cutting systems are equipped with high-definition cameras and specialized tools, allowing us to perform precise cuts, whether it’s removing obstructions, cutting through root intrusions, or trimming defective sections of pipe. This level of precision ensures minimal disruption to the rest of the pipeline and surrounding environment.

Robotic cutting is a trenchless technique, meaning there’s no need for digging or disruption to the surface. This reduces the cost, time, and environmental impact typically associated with traditional excavation methods.

Enhanced Safety:

Cost-Effective:

As the robotic cutter is remotely operated, the risk to workers is minimized. There is no need for technicians to enter confined spaces or hazardous areas, improving safety throughout the operation.

With robotic cutting, we eliminate the need for costly excavation, site restoration, and disposal of materials. The precise cutting reduces the amount of material that needs to be removed and replaced, leading to overall cost savings for the client.

Quick & Efficient:

Versatility:

Robotic cutting is faster than traditional methods, significantly reducing downtime and disruption to your operations. This is particularly valuable for critical infrastructure where minimizing service interruption is a priority.

Our robotic cutters can be used for a wide range of applications, from cutting tree roots and mineral build-ups to removing damaged sections of pipe or even performing internal pipe modifications

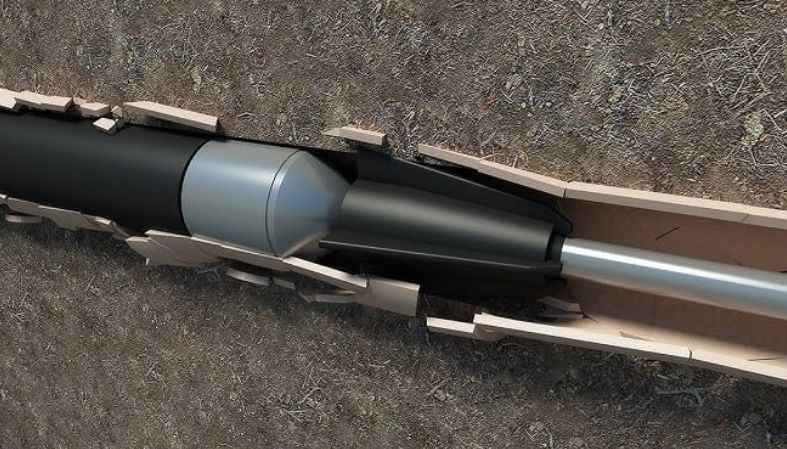

PIPE BURSTING

Pipe bursting is a trenchless method for replacing old or damaged pipelines with minimal surface disruption. The process involves breaking the existing pipe while simultaneously pulling in a new, durable pipe of the same or larger diameter. Ideal for upgrading water, sewer, and gas lines, pipe bursting is cost-effective, environmentally friendly, and reduces downtime compared to traditional excavation methods.

Proven Combination:

The dynamic bursting method, i.e. the combination of dynamic pile driving energy and the pulling force of a winch, is the longest proven method for underground pipe renewal. The simple but efficient procedure was developed more than forty years ago and is still used worldwide today.

Purposeful Guidance:

With a pulling winch, the guidance of the Grundocrack is statically supported by means of a steel cable in the old pipe. The winch is designed in such a way that the tension of the pulling rope is kept constant even in the case of increased resistance, e.g. due to pipe sleeves.

Strong Piece:

Just like the static method, dynamic bursting means a completely new pipe with a new service life of 80-100 years in the existing route. The Grundocrack is particularly suitable for the renewal of old pipes made of brittle materials such as concrete, stoneware, fibre cement (incl. asbestos cement), grey cast iron.

Brittle Materials:

The Grundocrack can be used to pull in new long or short pipes. Work can be carried out from pit to manhole or from pit to pit – with the mini machines even from manhole to manhole. The reverse gear makes it easy to detach the cracker from the expander when space is limited.

Flexible Use:

The heavy-duty, solid casing of the Grundocrack, is made in one piece from a forged piece, has neither welded seams nor screwed connections and is chrome-plated inside and out. The precise deep-hole drilling ensures direct force transmission from the piston to the head.